In the intricate network of a modern vehicle, custom automotive wire harnesses serve as the unsung heroes, ensuring seamless communication between various components. As vehicles become more advanced and sophisticated, the demand for custom solutions has surged, giving rise to a dynamic industry of manufacturers catering to unique specifications and requirements. In this comprehensive blog, we embark on a journey to unravel the significance of custom automotive wire harnesses, explore the process of obtaining a bespoke solution, delve into the qualities to look for in manufacturers, and shed light on the intricacies of the manufacturing process.

Intro to Custom Automotive Wire Harnesses and Manufacturers

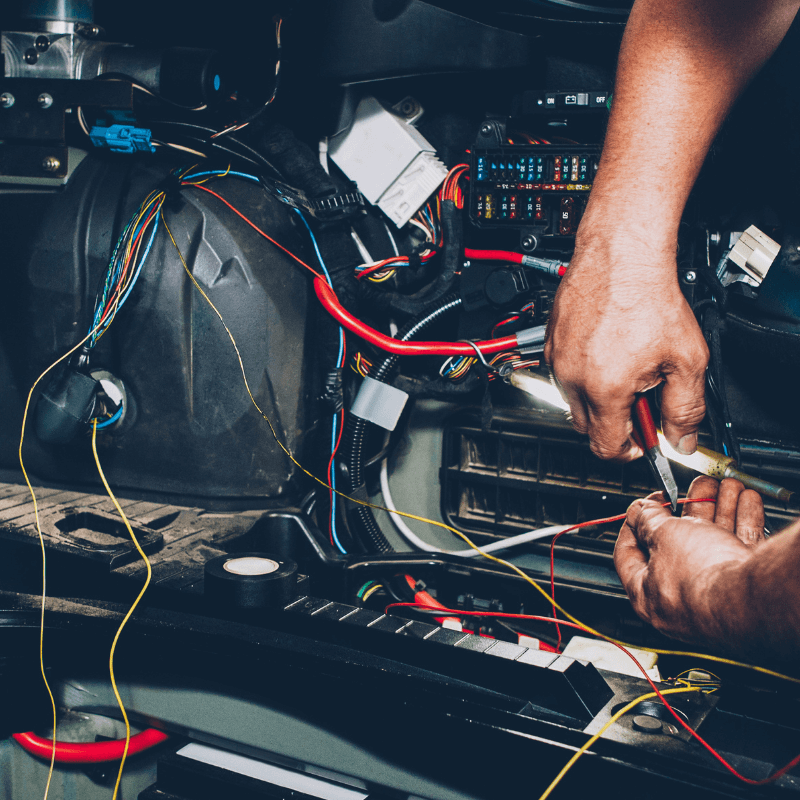

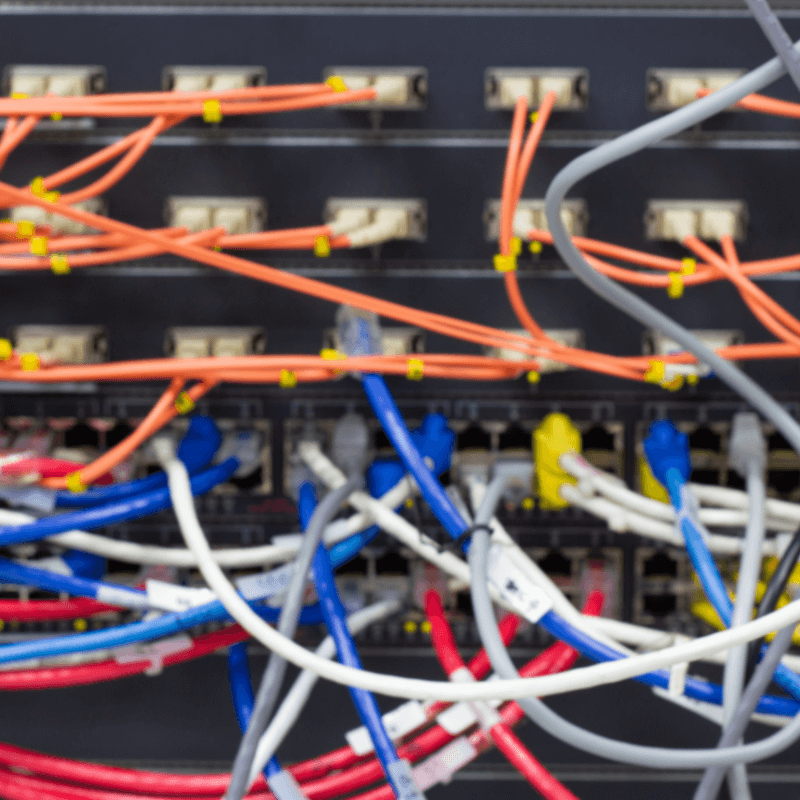

In the heart of every vehicle’s electrical system lies a complex web of wires meticulously organized into a custom automotive wire harness. These harnesses play a pivotal role in transmitting power and signals to different components, ensuring the smooth operation of a vehicle’s various functions. The surge in the demand for customized wire harnesses stems from the need to address specific requirements posed by diverse automotive applications. Whether it’s a high-performance sports car, an electric vehicle, or a rugged off-road machine, each demands a tailored wiring solution. This surge has given rise to a specialized niche within the automotive industry – custom automotive wire harness manufacturers.

The Significance of Custom Automotive Wire Harnesses

Custom automotive wire harnesses are not just a luxury but a necessity in the contemporary automotive landscape. Vehicles today are equipped with a myriad of electronic components, from advanced infotainment systems to intricate engine management systems. A one-size-fits-all approach no longer suffices in meeting the unique demands of different vehicles, each designed for specific purposes and operating conditions.

These custom solutions offer several advantages, including optimized space utilization, improved durability, and enhanced overall performance. For example, in electric vehicles (EVs), where the complexity of the electrical system is heightened, a precisely engineered custom automotive wire harness ensures efficient power distribution, contributing to the vehicle’s range and overall reliability.

Can I Have a Custom Automotive Wire Harness Made?

The accessibility of custom automotive wire harnesses to individuals and businesses has become a pertinent question in the automotive enthusiast and DIY communities. The answer is a resounding yes. Contrary to the belief that customized solutions are exclusive to large-scale manufacturers, many reputable manufacturers, like Ric-Tronics, cater to the specific needs of individuals, small businesses, and major automotive players alike.

The benefits of having a custom automotive wire harness made specifically for your application are manifold. Off-the-shelf harnesses might provide a quick fix, but they often compromise on factors like space efficiency, compatibility, and overall performance. Custom solutions, on the other hand, ensure that every inch of wiring is designed with the vehicle’s unique specifications in mind, resulting in a system that seamlessly integrates with the existing setup.

Navigating the Customization Process

Embarking on the journey of obtaining a custom automotive wire harness involves a collaborative process between the client and the manufacturer. It typically begins with a comprehensive understanding of the vehicle’s requirements, including the electrical components involved, the intended use, and any specific environmental factors that may influence the harness design.

- Design Phase: This initial stage is crucial, as it sets the foundation for the entire customization process. Manufacturers like Ric-Tronics work closely with clients during the design phase to create a blueprint that aligns with the specific needs of the vehicle.

- Material Selection: The choice of materials is another critical aspect of customization. Depending on the vehicle’s application and operating conditions, manufacturers carefully select materials that offer optimal durability, resistance to environmental factors, and efficient signal transmission.

- Collaboration: The collaboration between the client and the manufacturer doesn’t end with the design. Continuous communication ensures that any adjustments or refinements can be made throughout the manufacturing process, guaranteeing that the final product meets or exceeds expectations.

Qualities to Look for in Custom Automotive Wire Harness Manufacturers

Selecting the right manufacturer for your custom automotive wire harness is paramount to the success of your project. Several qualities distinguish reputable manufacturers in this specialized field:

- Experience: Look for manufacturers with a proven track record in the industry. Companies like Ric-Tronics, with years of experience, bring a wealth of knowledge and expertise to the table.

- Certifications: Ensure that the manufacturer adheres to industry standards and holds relevant certifications. For instance, Ric-Tronics, as a trusted player in the field, complies with rigorous quality standards, including AS9100 certification.

- Customization Capabilities: Evaluate the manufacturer’s ability to offer bespoke solutions. A manufacturer like Ric-Tronics, known for its commitment to customization, is well-equipped to address a wide range of requirements.

- Quality Assurance: Opt for manufacturers that prioritize quality assurance throughout the manufacturing process. Rigorous testing and inspection procedures, such as those employed by Ric-Tronics, ensure that each custom automotive wire harness meets the highest standards.

Industry Trends and Innovations

The landscape of custom automotive wire harness manufacturing is not static. It evolves with technological advancements and the changing demands of the automotive sector. Several trends and innovations shape the current state of the industry:

- Integration of Advanced Materials: The use of advanced materials, such as high-performance polymers and lightweight alloys, enhances the durability and efficiency of custom automotive wire harnesses.

- Smart Manufacturing Technologies: Industry 4.0 technologies, including automation and data analytics, are gradually making their way into custom automotive wire harness manufacturing. These innovations streamline production processes, improve efficiency, and ensure consistent quality.

Frequently Asked Custom Automotive Wire Harness Questions

How Do You Manufacture a Custom Automotive Wire Harness?

Manufacturing a custom automotive wire harness involves a series of meticulous steps to ensure precision, reliability, and durability. The process includes:

- Design and Planning: Collaborative design with the client, outlining specifications and requirements.

- Material Selection: Choosing appropriate materials based on the application and operating conditions.

- Cutting and Stripping: Preparing wires to the required lengths and stripping insulation for termination.

- Crimping and Termination: Attaching terminals and connectors to the wires, ensuring secure connections.

- Harness Assembly: Organizing and bundling wires into the desired configuration, ready for installation.

- Testing: Rigorous testing to ensure the harness meets quality and performance standards.

- Quality Assurance: Final inspection and quality assurance checks before the harness is ready for delivery.

Is Ric-Tronics a Reliable Custom Automotive Wire Harness Manufacturer?

Yes, Ric-Tronics stands as a reliable and reputable custom automotive wire harness manufacturer with a commitment to excellence. With years of industry experience, adherence to stringent quality standards, and a dedication to customization, Ric-Tronics is a trusted partner for individuals, businesses, and major automotive players seeking tailored wiring solutions.

How Long Does It Take to Get a Custom Automotive Wire Harness Made?

The timeline for custom automotive wire harness manufacturing varies based on factors such as complexity, quantity, and customization requirements. Manufacturers like Ric-Tronics prioritize efficient processes without compromising on quality, working closely with clients to provide realistic timelines for project completion.

Conclusion

In the realm of custom automotive wire harnesses, the collaboration between clients and manufacturers like Ric-Tronics epitomizes innovation and precision. The ability to tailor solutions to the unique needs of each vehicle ensures not only optimal performance but also sets the stage for the continued evolution of the automotive industry. As vehicles become more advanced, the role of custom automotive wire harness manufacturers becomes increasingly vital, contributing to the seamless integration of technology and functionality within the automotive landscape.

Whether you’re a DIY enthusiast, a small business owner, or a major player in the automotive sector, the realm of custom automotive wire harness manufacturing opens doors to unparalleled possibilities. With the right manufacturer by your side, your vehicle’s electrical system can be transformed into a masterpiece of efficiency, reliability, and innovation. Choose customization, choose excellence – choose Ric-Tronics.